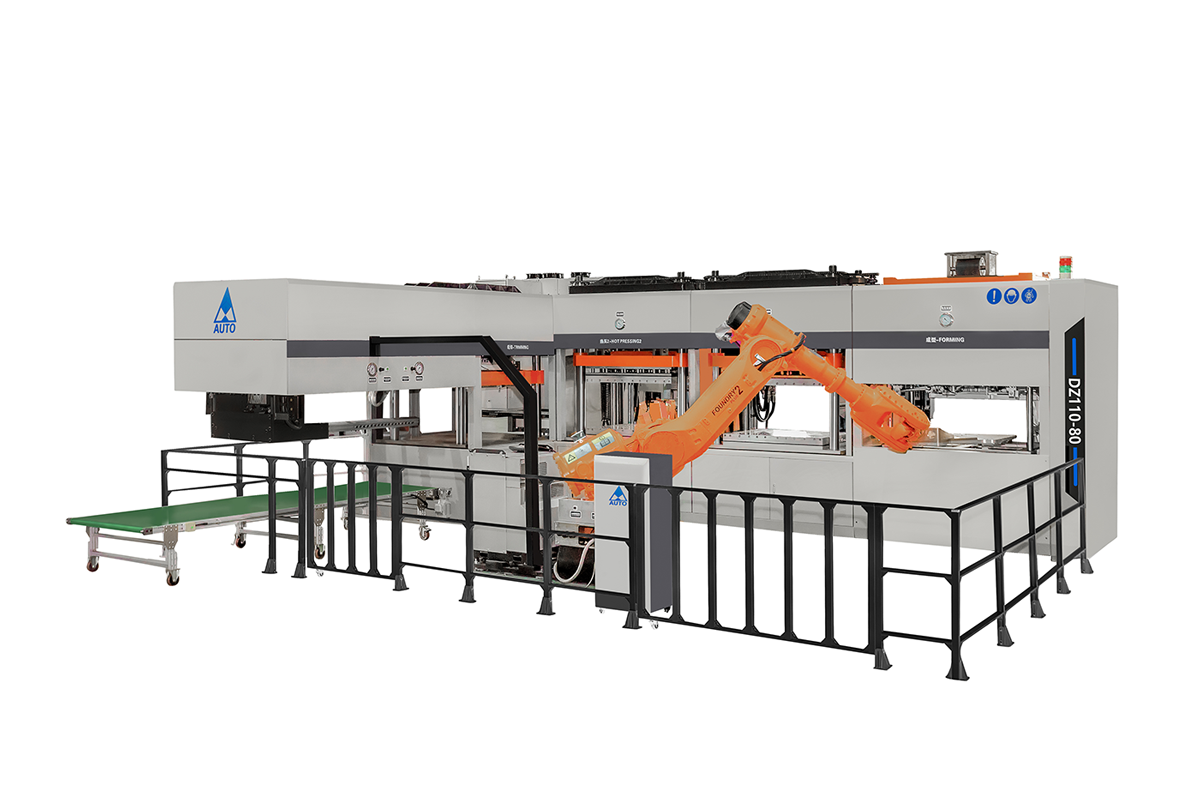

DM60-80 AUTOMATIC INTEGRATED BLISTER LAMINATING MACHINE

Specification Information

| Model |

DM60-80 |

| Film material |

PE, PLA, PHBT, PP, EVOH, etc. |

| Material for blister |

PET, PS, PP, PVC, etc. |

| Forming size |

600mm x 800mm |

| Max. Forming depth |

120mm |

| Heating Power |

13 kw |

| Max. trimming pressure |

60 ton |

| Production Speed |

10-20 cycle/min |

| Power consumption |

12 - 18 Kw·h |

| Vacuum consumption |

2600L/min |

| Machine dimension |

11.3m X 4.2m X 3.1m |

| Weight |

16ton |

| Rated power |

59kw |

Features

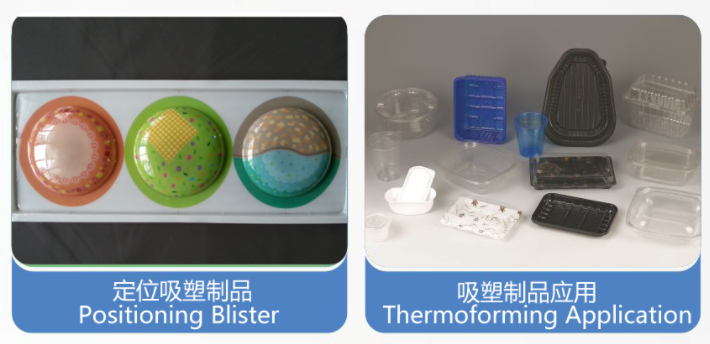

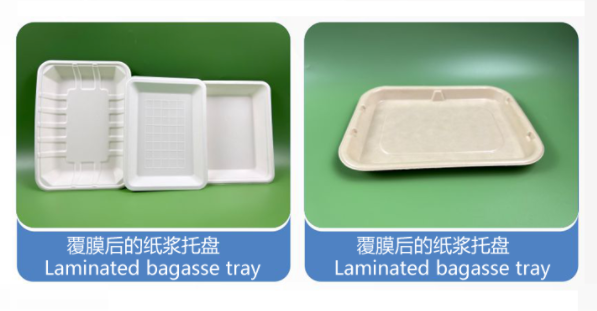

- Laminating Application

| 1) Max lamination production speed can be up to 20 cycle per min.

2) Servo control of the whole machine, high production capacity, low energy consumption, energy saving of more than 70% and capacity increase of more than 5times efficiency. 3) Fully automatic one click production: feeding, film feeding, product collection, and edge material automatic collection. 4) Two laminating station, manipulator feeding and double feeding station, can achieve automatic production without interruption. It not only improve production speed, but also allows for process control adjustment according to different production requirements. 5) Open stacking function, convenient product collection. 6) Automatic lubrication system, automatic timing oil supply. |

|

- Thermoforming Application